HIGH TEMPERATURE EPOXY ANCHORING

X500 650ML 1:1

Slow Cure Epoxy Resin Chemical Mortar

1:1 ratio 650ml epoxy base injection mortar for anchoring projects in high temperature country.

Use with universal 1:1 dispensing tools.

Two components pure epoxy summer epoxy adhesive is styrene free and low odor to fix machinery, staircases, reinforcement bars, rebars, and threaded rods to concrete, stone, masonry, brick, rock, and other construction fixings. Pure epoxy chemical anchoring system can provide a longer working time and have better flexibility during installation. It can be used indoors or in unventilated areas without health and safety concerns. There is also 600ml available in the range.

Chemical fixing system – Ultimate performance pure epoxy chemical anchor

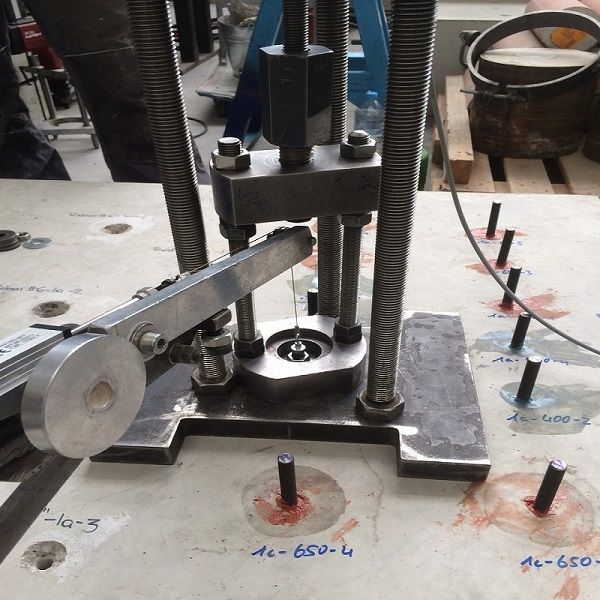

High-end epoxy mortar for heavy anchoring and critical conditions. In variation case of anchoring work which required higher performance to satisfy and secure the anchoring in dry, wet, uncracked, cracked concrete even in seismic conditions or temperature variation and installation limitation. We tested diverse anchoring condition in ETAG approval lab and with report to compare. Epoxy injectable adhesive anchor is strongest one of bonding fasteners which is growing demands.

Specification

- Material: Pure Epoxy

- Model Number: X500

- Size: 650ml

- Shelf Life: 18 months

- Mixing Ratio: 1:1

- Mixed Color: Gray

- Standard Package: One cartridge with one mixer

- Other Accessory: Mixer, caulking gun, nylon sleeve, air pump, brush

Features & Benefits

- Heavy duty load.

- Good chemical resistance.

- Ideal for deep embedment.

- Longer working time.

- No shrinkage.

- Bigger volume cartridge size can save more time to change new cartridges, more efficient.

- Styrene free and low odor. LEED tested for VOC (Volatile Organic Compounds).

- No health and safety concern to slow down your work.

Pure epoxy for large projects in construction and building

Excellent strength epoxy material is most requested by large constructions. The demand is growing as more concerns on anchoring secure and human errors. As advanced capability for rod and rebar doweling in concrete, epoxy anchoring is large consumption at building projects. Bigger volume saves more time to change new cartridges and more efficient.

Strongest epoxy anchoring for all fixing solution

Non-drip formula, ideal for overhead installation and suspension anchorage. Versatile and multi-purpose pure epoxy is longer curing time and more flexible on applications. As global warming, climate suitability and wide temperature applicability are important for chemical anchor development. We equip temperature facilities to simulate different anchoring temperature worldwide and do multiple testing to ensure the quality. The steady characteristic of epoxy is most used in tropical zone.

Technical Data

CHART 1. SOLID SUBSTRATE REBAR INSTALLATION DETAILS

| Pressure | Destroy Haul Strength (Kgf/KN) |

Safety Haul Strength (Kgf/KN) |

Working Standard (mm) |

||||||

| Concrete Strength | 4,000 psi | 280 kg/cm2 | 4,000 psi | 280 kg/cm2 | Hole Diameter | Hole Depth | |||

| Rebar No. | #3 | (Φ10) | 3,607 | 36.4 | 1,202 | 12.1 | 13 | 90 | |

| #4 | (Φ12) | 6,409 | 64.7 | 2,136 | 21.6 | 16 | 125 | ||

| #5 | (Φ16) | 9,695 | 97.9 | 3,232 | 32.6 | 20 | 145 | ||

| #6 | (Φ20) | 13,655 | 137.9 | 4,552 | 46.0 | 25 | 170 | ||

| #7 | (Φ22) | 18,672 | 188.6 | 6,224 | 62.9 | 28 | 200 | ||

| #8 | (Φ25) | 24,032 | 242.7 | 8,011 | 80.9 | 32 | 225 | ||

| #9 | (Φ28) | 27,364 | 276.4 | 9,121 | 92.1 | 37 | 260 | ||

| #10 | (Φ32) | 31,730 | 320.5 | 10,577 | 106.8 | 40 | 290 | ||

| #11 | (Φ36) | 35,843 | 362.1 | 11,948 | 120.7 | 42 | 320 | ||

| Remarks: | 1. Concrete Strength fc’: 280kg/cm2 (4,000 psi) 2. Rebar Strength: #3~#5 fy: 2,800 kgf/cm2, #6~#11 fy= 4,200 kgf/cm2 |

||||||||

CHART 2. CURING TIME TABLE

| Temperature (°C) | Gelling | Full Curing |

| 5~10 | 1-2 hr. | 90 – 100 hr. |

| 10~20 | 30-60 min. | 30 – 60 hr. |

| 20~30 | 14-30 min. | 14 – 22 hr. |

| 30~40 | 10-20 min. | 6 – 12 hr. |

| Please make pull out test over 24 hours after full cured. | ||

CHART 3. FIXING CONSUMPTION PER CARTRIDGE

| Anchor Size | Hole Diameter (mm) |

Hole Depth (mm) |

Number of Fixings |

| 650ml | |||

| M8 | 10 | 80 | 80 |

| M10 | 13 | 90 | 42 |

| M12 | 16 | 120 | 21 |

| M16 | 20 | 145 | 11 |

| M20 | 25 | 170 | 6 |

| M24 | 28 | 210 | 4 |

| M30 | 35 | 270 | 2 |

| M36 | 40 | 330 | 1 |

| Note: Based on continuous installation without interruptions or nozzle changes. Provided as a guide and will vary with temperature. | |||

The secret to extruding 600/650ml cartridge – pull the trigger with a rhythm

600ml/650ml side by side tube is quite big and contains a lot of resin mortar inside. Please pump the resin mortar out from the tube slowly just to allow the resin mortar flowing out from the opening of the tube. Don’t pull the trigger too fast. While pumping too fast, the mortar cannot make it to flow out from the opening of the tube, the pumping pressure will force some mortar coming out from the back plunger or cause the caulking gun stuck. So, in order to have the best performance, please pump the mortar slowly with a rhythm. Don’t pump too fast suddenly. While using electrical cordless caulking gun, also please notice the pumping speed.